Complete Guide To Paint Booths: Types, Uses & Benefits from SETS Machinery

Complete Guide To Paint Booths: Types, Uses & Benefits from SETS Machinery

A paint booth is an enclosed or semi-enclosed structure designed to ensure safe, clean, and efficient application of paints, coatings, or finishes to a variety of surfaces. It provides a controlled environment that prevents contamination from dust, fumes, and airborne particles while ensuring consistent, high-quality paint application.

At Surface Edge Technology and Solutions (SETS Machinery), a trusted paint booth manufacturer in India, we specialize in building advanced paint booths that feature ventilation, filtration, and overspray control systems. Our systems are designed to protect the product, improve operator safety, and meet stringent environmental and industrial safety standards.

There are primarily three types of paint booths—Pressurized Paint Booths, Dry Filter Paint Booths, and Water Wash Paint Booths—each designed to meet different production needs, materials, and coating types. SETS Machinery, a prominent paint booth manufacturer in Rajasthan, delivers reliable and efficient paint booth solutions for a wide range of industries.

Types of Paint Booths by SETS Machinery

As a prominent paint booth manufacturer in Jaipur, Rajasthan, SETS Machinery offers three major types of paint booths, each tailored for specific surface finishing needs:

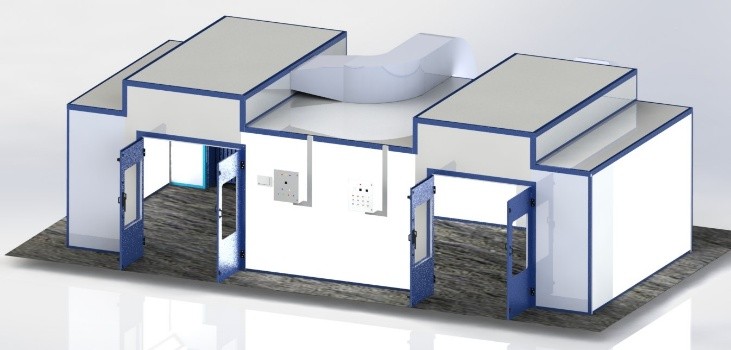

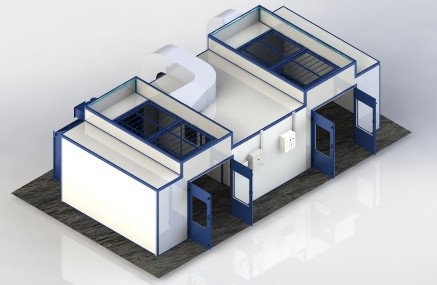

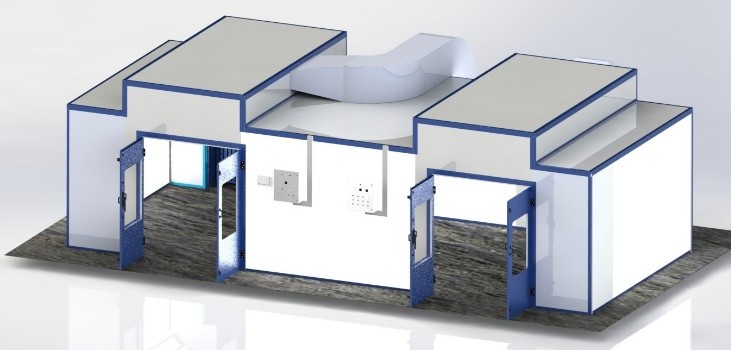

1. Pressurized Paint Booth

• How it works: Maintains positive air pressure to block dust and contaminants from entering the painting area.

• Ideal for: High-precision applications in the automotive, woodworking, and metal fabrication industries.

• Features: Enclosed design, air filtration, separate finishing and drying chambers, with optional automation like conveyors.

• Key Benefit: Delivers a clean, dust-free environment for superior surface quality.

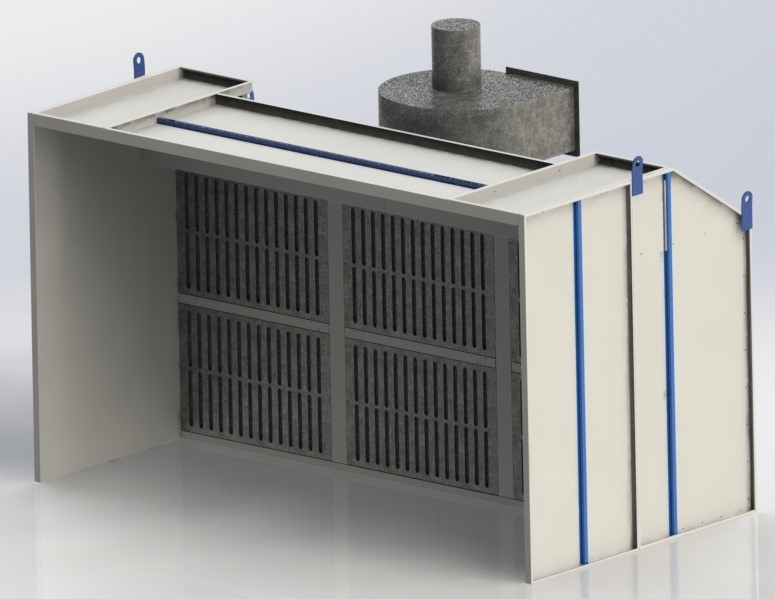

2. Dry Paint Booth (Dry Filter Booth)

• How it works: Uses replaceable filters to trap paint overspray—no water required.

• Ideal for: General-purpose or low to mid-volume production where simplicity and maintenance are key concerns.

• Features: Easy installation, cost-effective, low upkeep.

• Key Benefit: Eco-friendly and budget-conscious solution with minimal waste.

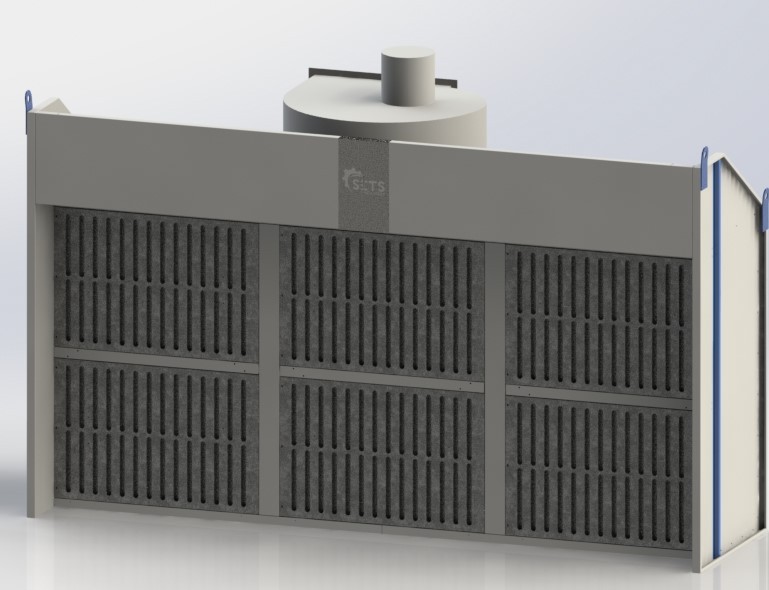

3. Water Paint Booth (Wet Type Booth)

• How it works: Utilizes a water wall or water curtain to capture and neutralize paint overspray.

• Ideal for: High-volume operations and sticky or high-solid paint applications.

• Features: Effective filtration, sludge collection systems, ideal for demanding environments.

• Key Benefit: Maintains air quality and manages overspray effectively in industrial-scale setups.

Applications of Paint Booths in Manufacturingy

Paint booths are essential for industries that require clean, consistent, and safe finishing processes. Common applications include:

• Automotive Industry

Spray painting of vehicle bodies, parts, and accessories with uniform finishes that meet environmental standards.

• Woodworking Industry

Finishing wooden furniture, cabinets, and doors while minimizing dust contamination and enhancing aesthetics.

• Metal Fabrication

Coating machinery parts, tools, and equipment to boost corrosion resistance and surface durability.

• Appliance & Equipment Manufacturing

Protective coatings for home and industrial appliances, ensuring visual appeal and extended lifespan.

• Aerospace and Defense

Precision coating of sensitive components with a focus on reliability, safety, and durability.

Key Benefits of Using Paint Booths from SETS Machinery

As a leading paint booth supplier from Jaipur, SETS Machinery ensures top-quality, custom-built solutions with the following advantages:

• Dust-Free Finishing Environment – Protects paint jobs from airborne particles and ensures flawless coating.

• Consistent High-Quality Finish – Controlled airflow and humidity promote smooth, uniform application.

• Enhanced Operator Safety – Proper ventilation and filters reduce exposure to hazardous fumes and chemicals.

• Compliance with Environmental Norms – Reduces VOCs and paint overspray to meet environmental regulations.

• Improved Workflow Efficiency – Integrates with automated systems like conveyors to boost productivity.

• Lower Paint Waste and Cost – Efficient spraying systems reduce material waste and optimize paint usage.

How to Choose the Right Paint Booth

When selecting a paint booth, consider these factors:

• Type of material: Wood, metal, plastic, or composites

• Production volume: Low, medium, or high

• Type of paint or coating used

• Desired surface finish quality

• Budget constraints and environmental regulations

Choosing the right paint booth system is crucial for product quality, operator safety, and operational efficiency. At SETS Machinery, we combine innovation, engineering expertise, and industry experience to deliver reliable paint booth solutions for every surface finishing need—whether it's in automotive, woodworking, metalwork, or industrial manufacturing.

Upgrade your finishing process with SETS Machinery – India’s trusted paint booth manufacturer. Contact us today to find the perfect solution for your production line.